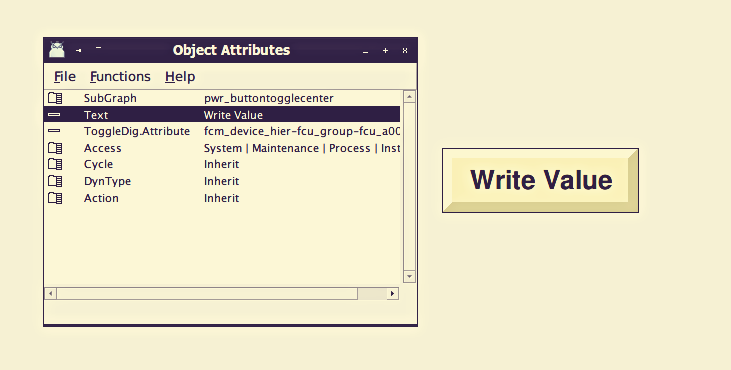

Graphical objects in ProView are providing two types animations and behavior attributes, where both can be highly customized. Dynamics are those animations related on how the object operates with the environment — mouse and keyboard — and the logical plant nodes. At the other side, actions are those XTT commands triggered with the user interaction. So, for example we have the Electric > ControlSwitch sub-graph, which has the action DigShift, but we can change the DigShift action to ToggleDig, allowing a digital input switching between True and False, and preserve the rotate animation which is inherited from its definition.

Is really nice to have such type of graphical objects, because we can mix different types of animations, user interface behaviour and XTT commands, allowing almost any type of control to be created, including custom sub-graph objects, which can be linked with custom C or C++ programs. You just need to remember the $object and $local object references once your are instantiating the sub-graph object, mainly once they are pointing to logical plant nodes. Thanks to this flexibility, you can manage for example a simple PushButton, and make it work as SwitchButton, and make it work as ControlSwitch to toggle a digital input value.

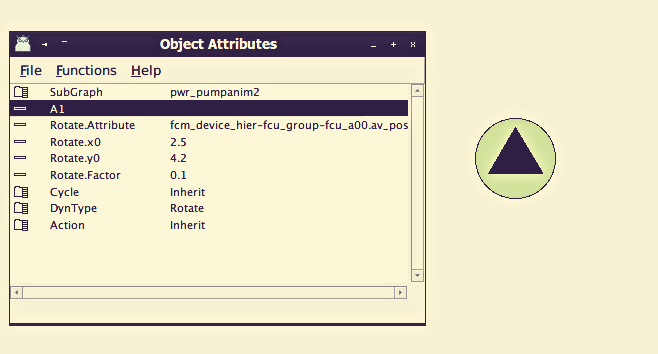

For example we can use a PumpAnim2 sub-graph object and change its dynamics to be a rotating animation, rather than using its default, we just need to ensure that the dynamic is linked to the proper object — for example an analog signal on rotate animations — and configure each dynamic attribute correctly, as it was done using the rotate facto on the case above.

You have many options to use in your HMI once you are building your ICS applications using ProView. You can read the Design Guide, the Ge Reference Manual, the SubGraph Reference Manual and the Operator Guide. The Operator Guide mainly contains the list of XTT commands, if you need to use any XTT script based commands to work the logical plant. This is really nice, because you can trigger — with a proper design — custom actions inside your rt_appl based application if you need make something complex, like distributing some task in a period, like moving a pump for 20 minutes and monitoring how filled is a tank, blocking its pumping action if it is required. Tasks like that are complex to implement using PLC programming, so a good C or C++ application can do that.